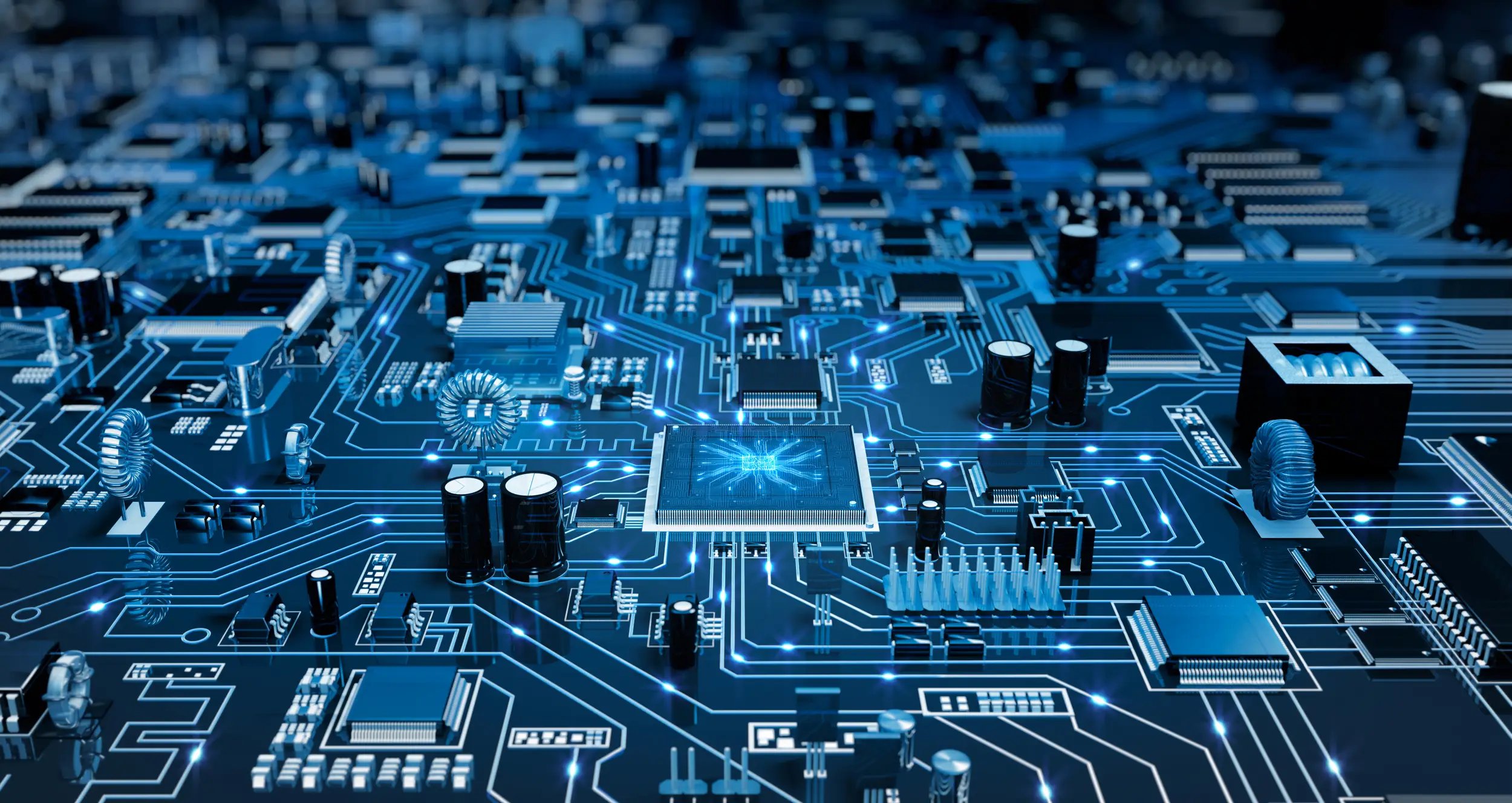

PCB boards, short for Printed Circuit Boards, are the backbone of modern electronic devices. They play a crucial role in connecting various electronic components, providing stability, and enabling efficient functioning. In this comprehensive guide, we will delve into the intricacies of manufacturing PCB boards, their importance, types, advantages, applications, and future trends.

What are PCB Boards?

They are flat, laminated boards made of non-conductive substrate materials like fiberglass, epoxy, or polyimide. They have conductive pathways etched or printed onto them, forming circuits that allow electrical signals to flow between components.

Importance

They are essential in electronics as they provide a sturdy platform for components, reduce wire clutter, enhance electrical connections, and enable compact device designs.

Types of PCB Boards

There are several types of that, including single-sided, double-sided, multi-layered, rigid, and flexible PCBs. Each type serves specific purposes based on the device’s requirements.

Manufacturing Process

The manufacturing process of that involves several stages, starting from designing the layout to finalizing the board for use.

Designing PCB Layout

The first step is designing that layout using specialized software. This involves placing components and creating pathways for electrical connections.

Printing the Circuit Board

Once the layout is finalized, it is printed onto the substrate using a process called etching. This creates the conductive pathways on the board.

Etching and Drilling

After printing, the excess copper is etched away, leaving behind the desired circuit pattern. Holes are drilled for component mounting and interconnections.

Plating and Finalizing

The board undergoes a plating process to reinforce the circuit traces. Components are then soldered onto the board, and it undergoes testing to ensure functionality.

Advantages

This boards offer numerous advantages, including:

Reliability

They provide reliable connections, reducing the risk of loose connections or electrical shorts.

Compact Design

This boards enable compact device designs, saving space and enhancing portability.

Easy Repairs

Faulty components can be easily identified and replaced on that boards, making repairs straightforward.

Applications

PCB boards find extensive use in various industries, including:

Electronics Industry

They are integral to the production of smartphones, computers, and other consumer electronics.

Medical Devices

PCB boards are used in medical equipment like MRI machines, pacemakers, and monitoring devices.

FAQs

- What are the main types of PCB boards?

- Single-sided, double-sided, multi-layered, rigid, and flexible PCBs.

- How are PCB boards designed?

- Using specialized software to create layouts and pathways for electrical connections.

- What are the advantages of using PCB boards?

- Reliability, compact design, and easy repairs are some key advantages.

- Which industries heavily rely on PCB boards?

- Electronics and medical industries heavily rely on that.

- What innovations can we expect in that technology?

- Innovations such as flexible boards and higher circuit density are expected in the future.

Conclusion

In conclusion, that boards are vital components in modern electronics, offering reliability, compactness, and ease of repair. As technology advances, we can expect further innovations in that board manufacturing, such as flexible and high-density boards.

Also, Reads More>>>Cold Weather Golf Essentials